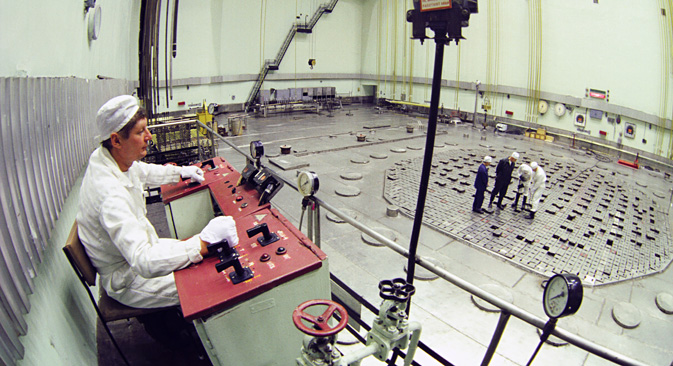

Siberian Chemical Plant. Source: A.Solomonov / RIA Novosti

New beryllium production technology will alleviate Russia’s need to import this rare and valuable metal, according to scientists from Tomsk Polytechnic University and the Siberian Chemical Plant. In late January 2015 they jointly produced the first laboratory sample of 100 grams.

The next step for scientists is to produce 1-2 kilograms of metal beryllium. Industrial production of beryllium in Russia could start as early as 2020. Investments for the plant are estimated at $30 million, with expectations being that the project will be implemented over five years.

"Our proposed technology is characterized by the closed technological cycle technique and the ability to extract not only metallic beryllium, but also accompanying commercial products - synthetic calcium fluoride and silicon oxide," said Alexander Dyachenko, vice rector for Research and Innovation at Tomsk Polytechnic University.

New technology also helps to preserve other valuable minerals such as fluorite. "Substantial chemical enrichment and de-siliconization of fluorite occurs in the process," Dyachenko said. Fluorite is used in optics, chemicals, metallurgy and other industries.

Scientists propose using a bertrandite-phenacite-fluorite concentrate from industrial Yermakovskoye mine deposits as a raw material.

Space age metal

Beryllium is one of the world's most precious metals. Defense ministries across the globe treat it as a "strategic and critical material," as it is used in the nuclear and aerospace industries. Scientists call beryllium a "space age metal" or a "metal of the future."

The price of pure beryllium, according to the U.S. Geological Survey, is $500 per kilogram. Incidentally, the cost of beryllium has grown by about half over the last decade mainly due to its demand in the world market and its limited scope of primary production.

According to statistics from the U.S. Geological Survey for 2012, the volume of production of beryllium in the world amounted to 230 tons, of which 200 tons came from the U.S., 25 from China, and several tons from Kazakhstan. Until recently, the Ulba Metallurgical Plant in Kazakhstan, Brush Wellman in the U.S. and the Chinese company SKS were the only ones to possess the technology to produce beryllium.

Strategic reserves are running out

It is difficult to say yet whether the new technology developed by scientists will be able to change the balance of power in the world market. The mining infrastructure of the Yermakovskoye deposit is in a poor state, says Mikhail Popov, an associate professor at the Ural State Mining University. "We need to re-evaluate the reserves," he said.

"It will be interesting to see how beryllium ores from the Mariinsky deposit in the Urals – represented by another silicate of beryllium, beryl – will react to the new technology," Popov said. He says that in the Soviet era this deposit was the main source of beryllium ores, which still has considerable reserves.

Additionally, beryllium is a toxic metal, which increases the cost of production. "The production of beryllium on outdated technology pollutes groundwater and the environment, and therefore requires an exclusion zone of at least 200 kilometers," Popov said.

Whether the new technology developed in Tomsk will make the process more environmentally friendly will be clear when scientists produce the second laboratory-extracted sample of beryllium.

All rights reserved by Rossiyskaya Gazeta.

Subscribe

to our newsletter!

Get the week's best stories straight to your inbox